Bearing Applications

Bearing Applications

Blog Article

Bearing Applications

Bearings play a critical role in a wide range of machines and mechanical systems by enabling motion and reducing friction between moving parts. The applications of bearings are extensive and can be found in various industries such as automotive, aerospace, industrial, and more.

Automotive Industry

In the automotive sector, bearings are indispensable components used in engines, transmissions, wheels, and other vital parts to ensure smooth and efficient operation of vehicles. By reducing energy loss caused by friction, bearings contribute significantly to enhancing the overall performance and fuel efficiency of automobiles.

For instance, in modern electric vehicles, bearings are crucial for the functioning of electric motors and drivetrains. The high precision and low friction characteristics of bearings help optimize the performance and range of electric vehicles, making them more sustainable and environmentally friendly.

Aerospace Industry

Within the aerospace industry, bearings are integral to various critical systems in aircraft, including engines, landing gear, and control mechanisms. The reliability, precision, and durability of bearings are paramount in ensuring the safe and efficient operation of aircraft during flight, where any failure could have catastrophic consequences.

For example, in the design and construction of aircraft engines, specialized bearings are used to withstand high temperatures, extreme speeds, and heavy loads. These bearings are engineered with advanced materials and coatings to ensure optimal performance and safety in demanding aerospace applications.

Industrial Machinery

In industrial settings, bearings are utilized in a wide array of machinery such as conveyor systems, pumps, and motors to facilitate the smooth movement of components and ensure operational efficiency. The proper selection and maintenance of bearings are crucial in minimizing downtime and maximizing productivity in manufacturing processes.

For instance, in heavy-duty industrial applications like mining equipment, bearings are subjected to harsh conditions including heavy loads, high speeds, and contamination. Specialized bearings with enhanced durability and sealing mechanisms are employed to withstand these challenging environments and ensure reliable operation.

For more in-depth information on diverse bearing applications and their specific roles in various industries, you can explore further at Www.

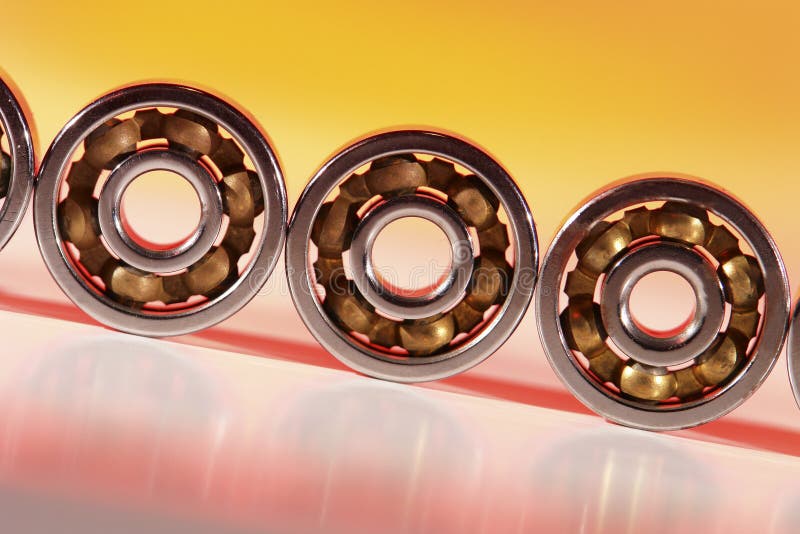

Benefits of Ball Bearings

Ball bearings are widely used across industries due to their efficiency, versatility, and numerous benefits that make them preferred choices in various applications.

Low Friction

One of the key advantages of ball bearings is their ability to minimize friction between moving parts, resulting in smoother operation and reduced energy consumption. This characteristic not only enhances the performance of machinery but also contributes to energy efficiency and cost savings.

High Precision

Ball bearings are renowned for their precision and accuracy in maintaining alignment and supporting loads, making them ideal for applications requiring tight tolerances and smooth operation. The high level of precision offered by ball bearings ensures reliable performance and longevity in critical machinery.

Low Maintenance

Due to their robust design and efficient operation, ball bearings require minimal maintenance throughout their lifespan, reducing downtime and maintenance costs. This low maintenance requirement makes ball bearings a cost-effective solution for applications where continuous operation is essential.

To delve deeper into the advantages of ball bearings and their suitability for different applications, you can explore further at Tapered Roller Bearings Or Spherical Roller Bearings.

Bearings Manufacturer

Choosing the right bearings manufacturer is crucial to ensuring the quality, reliability, and performance of bearings used in diverse applications across industries. A reputable manufacturer offers a wide range of bearing types, sizes, and materials to meet specific industry requirements and standards.

Quality Assurance

A trusted bearings manufacturer implements stringent quality control processes to guarantee that all bearings meet industry standards and specifications. By prioritizing quality assurance, manufacturers ensure the performance, durability, and safety of bearings in various applications, thereby enhancing overall operational efficiency.

Customization Options

Leading bearings manufacturers provide customization options to tailor bearings according to the specific needs and requirements of different applications. Customization may involve material selection, lubrication options, and design modifications to optimize bearing performance and longevity in specific operating conditions.

Technical Support

Collaborating with a reputable bearings manufacturer ensures access to technical support and expertise throughout the entire lifecycle of bearing usage, from selection and installation to maintenance. This technical support helps address any issues that may arise, optimize bearing performance, and maximize the efficiency of machinery and equipment.

For comprehensive information on different bearing types, manufacturers, and their unique offerings, you can visit Bearing Types You Should Know.

Report this page